I take pride in hand selecting all my Oahu grown wood.

There has been a good amount of mills popping up within the last 5 years to purchase lumber from. Most of these mills offer one piece slabs but only a few offer dimensional lumber.

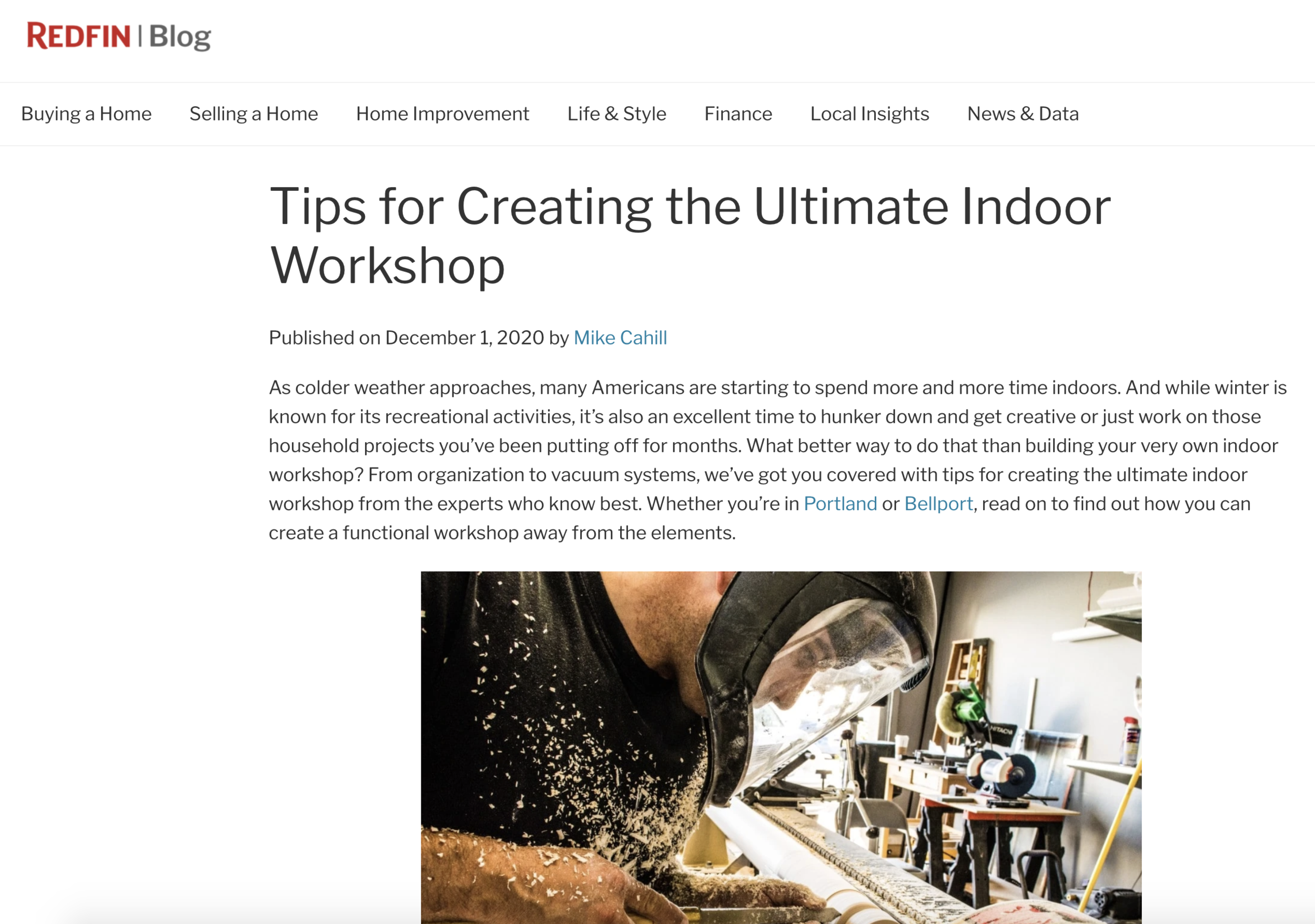

The dimensional lumber I get is all cut “quarter sawn” which is a certain cut and in the end means the wood stays stable throughout the drying process and beyond. The picture is taken at the sawmill in the back of Waimanalo, Oahu.

While one piece slabs can often purchased already dry, the dimensional lumber I still pick fresh of the mill and air dry them at my shop. Because the shop is located in a low humidity and warm area the wood drying time is between 6-12 month.

After the drying time, the wood is down to furniture building moisture level and is ready whenever I need to turn them into one of a kind furniture. Every piece has it’s own character and is a joy to watch transform in color and shape.